Table of Contents

Introduction

Primer bulbs are without a question extremely convenient for priming your engine. There is absolutely nothing wrong with them under normal operating conditions. Most paramotor manufacturers use them with minimal problems. They are also completely safe and appropriate on float bowl carburetors as they are not susceptible to most of the the problems we will go over.

The convenience of primer bulbs does not come without some fairly serious potential consequences when things don’t quite work as they should. These reasons should be considered by pilots and manufacturers because they have a lot of merit. Even Vittorazi Motors understands this and clearly outlines these potential issues in their installation manuals. Gladly most of the serious problems can be avoided by adequate maintenance so we want to cover what steps can be taken to avoid these problems and to consider if running a different priming method is more appropriate for you.

In this article we will reference the Vittorazi Installation Manual in several places. You may find this manual by going into the Services section on their website. You can also find the latest one here: Read Manual

Ok, so what exactly is the problem?

Walbro carbs were never intended to pull fuel from a large fuel tank below. They are designed for lawn equipment where the line is a maximum of 6″ long and the fuel tank is either above / same level as the carb or just slightly lower. They simply do not have a big pulse fuel pump so it comes with limitations.

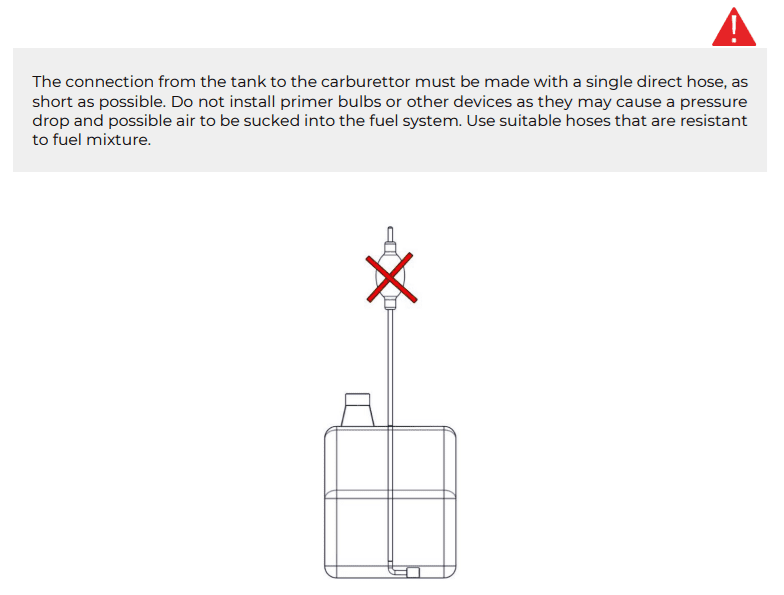

Again, Vittorazi gives clues about this in their installation manual. They recommend a MAXIMUM distance of 70cm from the very bottom of the fuel tank where the pickup is to the carburetor. No restrictions of any kind are allowed in this line. It should be a single 3/16″ (4.8mm) inside diameter fuel line from the fuel tank straight to the carburetor.

But everybody uses primer bulbs!!!

Correct. In the beginning of the article we specifically pointed out that primer bulbs work well except when something else doesn’t. This is where the danger lies and we will cover three main issues that stem from using them.

Issue 1: Potential fuel starvation (caused by other components)

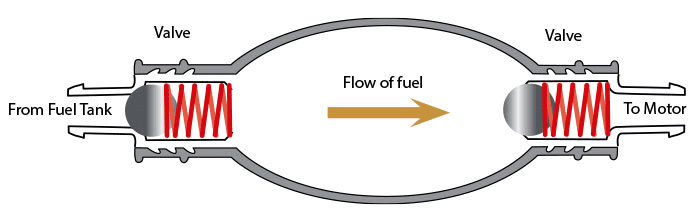

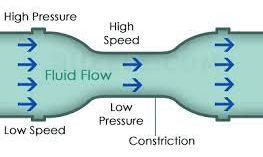

The first issue comes from potential fuel starvation at full power. The primer bulb creates two restrictions inside because it uses two check valves to control the input and output flow of fuel. Please refer to the diagram below. We borrowed the diagram from BoatUS’s article and you may read the original one here.

When the carburetor screen is clean and the in-tank fuel filter is regularly replaced, our fuel system can be considered fairly low restriction. The problem arises because paramotor pilots generally put off maintenance until something is wrong. In practice, we recommend replacing the in-tank fuel filter every season but many pilots don’t even know that there is a filter inside the tank, nor that it should be inspected and replaced regularly to prevent some very serious issues.

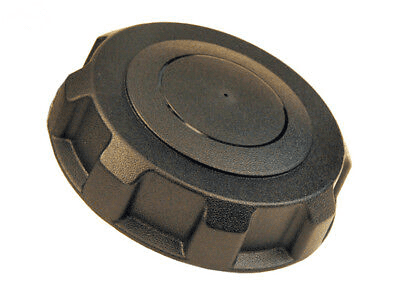

Another important restriction and failure point that needs to be addressed is the vented fuel cap. Usually they use a tiny hole which can get plugged and the integrated check valve is very stiff and provides a very low flow of air.

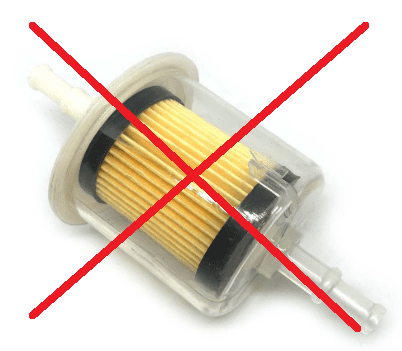

There is a point at which the fuel filter/screen will start to restrict the fuel flow. Having an in-line fuel filter, fuel cap check valve, flow meter, reducers, loops, too much fuel line length or pretty much anything else to the fuel line will compound this problem. Having a carburetor that has not been service for a long time that has stretched out diaphragms that are not as effective at pumping fuel will also drastically compound this problem.

Please, for the love of your paramotor (and your favorite choice of deity) avoid using in-line fuel filters at all cost. Especially if they are used in addition to the in-tank filter. They introduce ALL of the problems listed in this article (actual air bubbles, fuel vapor bubbles, restrictions and additional failure points).

Combined with the restriction from the primer bulb all of these things will lead to a minor fuel starvation issue which will happen at full power. This is not good! Full power is the last place where you want to reduce fuel. At best, the engine will overheat or bog down but the consequences can be much worse and can easily result in a holed piston or even a fully seized engine.

Issue 2: Air Bubbles / Fuel Vapor

There is a common misconception that all paramotors will have air bubbles in the fuel line and that they cannot be avoided. Ironically, the primer bulb is the main reason this is probably true but it’s not the full story.

There are two reasons for air bubbles in the fuel line. The first one is actual air that is being sucked into the fuel line from either incorrectly installed tube or from leaks in the fuel system components (between the fuel filter in the tank and the carburetor). We will cover the leaks that stem from aging primer bulbs in the next section.

The second reason for air bubbles is directly caused by the fact that the diaphragm pump inside the carburetor creates a vacuum on the fuel which will effectively pull vapor out of the fuel (you can sort of think about this like when we de-gas plastic resin in casting). This is referred to as vaporization. This can happen to some extent on any fuel system, however, just like the first issue, this is compounded by every single restriction that is added to the fuel line upstream from the carburetor. And yes, the primer bulb’s check valves are a huge contributor.

Having some fuel vapor in the fuel line is not the end of the world. However, depending on how the fuel line is routed, there can be multiple places where these bubbles are trapped and can grow in size and eventually release into the carb. This s also, you guessed it, not good!

Fuel vapor does not have the same density as fuel. When large bubble releases into the carburetor and it gets delivered instead of liquid fuel, it will create a temporary lean condition on the engine. Gladly, this would result in a sputter or engine out rather than actual engine damage since this happens so abruptly. Having said that, I can see several situations in which consistent fuel vapor bubbles could starve the carburetor for fuel, but not enough to stop the engine. This could lead to actual engine damage.

It’s worth mentioning that primer bulbs and other devices cause more vaporization in another way. When the fuel line changes sizes, it directly affects the speed at which the fuel flows and it creates areas of different levels of vacuum. In other words, on a Moster, the correct fuel line size is 3/16″ (or 4.8mm) inside diameter, however, the connections on the primer bulb are for 1/4″ fuel line. What’s worse is that the fuel line itself is essentially a large volume/space and the fuel accelerates as it goes back to the outlet especially at the point where the check valve restricts flow even further. In all honesty, this is probably one of the least dangerous aspects of this whole article but it is worth mentioning because all of these factors only matter in combination.

Issue 3: Failure Points / Outside Air Bubbles

The most obvious problem that can result from primer bulbs (and all other devices added to the fuel line) is the fact that they can crack as they age. They also introduce FOUR sealing connections which can all fail. These include the two fuel line connections to the primer bulb but also the connections between the metal “caps” and the rubber primer bulb itself. These connections can leak and when they leak, the carburetor will suck air through the cracks.

Remember, any time you add a connection to the fuel line, you are adding a potential failure point.

Most of these issues can be eliminated/avoided

The truth is: most of these issues can be eliminated and/or avoided (or at least reduced enough where they may not matter) with a clean routing and regular service.

Here are some general tips:

-

- Always use the shortest length of fuel line possible (on any fuel system).

-

- Always try to run a line that’s straight and always uphill. Any time the line has to go down-hill you will create a trap for air or fuel vapor bubbles to collect and release. This is not possible on all engines (Atom80) but avoid them as best as much as you can.

-

- Avoid fuel lines of different sizes. Even if it means working slightly harder to get the line on a bigger fitting.

-

- Service your fuel system every season. We strongly recommend replacing the fuel filter in the tank (including the short fuel line that attaches to it), new primer bulb, new fuel line and a full carburetor service.

-

- Generally avoid adding anything to the main line as much as possible (especially if you do run a primer bulb).

-

- Consider using another priming method all together.

Alternative Priming Systems

There are several other priming systems which can be added to paramotors. Some also have drawbacks and some are not nearly as convenient but for some pilots, this may be a very good option to consider, especially if you value reliability or don’t keep up with service.

Blow Tubes / Sealed Blow Tubes

An old school way to prime paramotors is a Blow Tube. Traditional Blowtubes kind of suck (or blow I suppose) because they smell and you have to blow really hard while trying to press a button and it’s very difficult to tell how much fuel is being delivered. They can also spill fuel while putting the paramotor on or connecting to your wing. Lastly, and most importantly, they also make your system open to the atmosphere which means the fuel is exposed to moisture… but worse, humidity from the air can now directly condense on the inside of the fuel tank and drip to the bottom of the tank. Trust me, this is not a good time.

Sealed Blow Tube (check valve)

We use this system on Iris Paramotors. A simple modification to the traditional blow tube makes this a very usable system that offers significant gains in reliability. It is not nearly as convenient as a primer bulb, however, having a check valve in the blow tube makes priming much easier and it allows the system to stay sealed from the elements. Also, the check valve holds the pressure in the tank after you stop blowing so you have time to press the metering bypass button on the carb.

We set our system up where you can see the main fuel line while using the blow tube so you know exactly when the fuel reaches the carb.

What all blow tubes offer that’s a massive improvement is a redundant, high-volume venting system. The tiny hole in the fuel tank cap (with a check valve usually) is a big restriction for the carb to work against. It can get clogged very easily, especially in dusty climates. Since a small amount of fuel/oil can still collect at the vent, any foreign particles will stick to it and eventually build up enough to stop it from working.

The redundant vent takes a big load and allows the carb to pump easily and freely and drastically improves reliability of our paramotors.

Let’s face it. Nobody wants to blow into a tube to prime their paramotor (especially while making eye contact) but the benefits can drastically outweigh the costs for most pilots and this system not only offers a lot of benefits, it also makes a much more reliable paramotor.

Parallel primer bulb circuit

We won’t go too much into this one because it’s pretty self-explanatory. A second fuel line can be ran in parallel to the main one with a priming bulb and the fuel can be injected into the intake through a drilled hole. This can be done before the carb or before the reeds.

This system works great but it comes with one drawback: It does not prime the main fuel line and it can take the engine several cycles (or the whole prime) to just pump the fuel to the carb. This means it can still take a couple of tries to start the engine.

Please reach out to Neil from Aviator if you want to ask questions about this system.

Lawn Equipment Style Primer

Another parallel priming system that can be used is the same thing that’s used on lawn equipment like chainsaws. We don’t like this one as much because it’s more involved and creates several failure points and maintenance items but it’s been used on several paramotors before. What’s really nice about it is that it delivers fuel directly inside the carb, but in a parallel circuit.

Two holes must be drilled into the over of the carburetor and two small hose barbs are pressed in and sealed. One of the lines drains back to the tank and the other runs to the output side of small chainsaw style primer button. The input side of the primer button runs to a separate pickup inside the fuel tank.

This system is great and very clever but it requires significant work and introduces at least 10 potential problem spots. Also, any air that can be sucked in by this system will also inevitably end up inside the carb. This means that although it is a parallel system, the possibility of air intake is actually doubled.

Conclusion

Whew, thank you for hanging through for this one. In case you can’t tell, I’m very passionate about this topic because it’s a very important one. Many problems and motor failures have been caused by some of the issues in this article and I hope it helps you make a safe and reliable paramotor (even if it just reminded you to replace your fuel filter).