The Ultimate Flying Machines

At Iris Paramotor we believe that the term “Paramotor Manufacturer” should mean something. We are an honest and hard working company in an industry driven by hype and dishonest marketing. We are the only company in the USA that turns raw materials into paramotor frames, completely in house. This is our core operating principle for all of our paramotors and accessories since the start of the company (we’ve been doing it since before it was cool).

Our paramotors are strong, innovative and some of the best looking units on the market. We offer regular improvements and updates rather than cashing in on the same frame for 5-10 years like other companies. If something doesn’t work, we improve it. If a customer tells us a good idea, we will make it.

Our team of skilled employees designs, tests, machines, fabricates, welds, powder coats, anodizes and even injection molds all the components from a wide array of materials including all types of metals and advanced polymers. We do all of this the hard, expensive way because we have a passion for what we do and want to offer the highest level of quality and performance that you deserve as a pilot. We give you all of that value at a competitive price compared to other manufacturers.

EXCELLENTTrustindex verifies that the original source of the review is Google. Just received my Iris Throttle today. It's perfect! Thanks man!Posted onTrustindex verifies that the original source of the review is Google. My first paramotor purchase! I’m a believer in doing business with quality people. Very quickly into researching equipment I learned that the PPG community has some shady vendors. Dmitri was a delight to work with and open about pros and cons of his and other equipment on the market. As a bigger guy at 6’6” and 260lbs I was looking for 140 machine and possibly the Polini 202. The Infinity XL checked alll the boxes and even has a little more room between swingarms. I was able to bring my instructor along to pick up the machine so we both got familiarity and were able to talk shop. Great doing business with Iris and Dmitri! Highly recommend.Posted onTrustindex verifies that the original source of the review is Google. Beautiful product, and great customer service! When I was ready to order my paramotor, Dmitri answered all of my questions and the experience made my decision very easy. I am loving my Iris Infinity, and would recommend Iris to anyone in the market for a new machine. Truly a work of art!Posted onTrustindex verifies that the original source of the review is Google. After ordering many parts from IRIS the service has been outstanding. Quality material, quick response etc. Everything anyone would want/ need! Strongly recommendPosted onTrustindex verifies that the original source of the review is Google. I've bought throttles, quick release hubs and random Paramotor parts from Iris Paramotor. The common theme every time is great customer service, willingness to help, fast shipping, and great parts. Keep innovating Iris!Posted onTrustindex verifies that the original source of the review is Google. Dmitri and his team are starting to become a staple in the paramotor community in the US. Always answering questions and helping folks out in this sport with the wealth of knowledge. It's a tough business to be in and I want to acknowledge the efforts they go through to ensure their customers are satisfied. Their machines are well engineered and their cost are not prohibitive. I hope to support them in the future and would refer any pilots to iris Paramotor.Posted onTrustindex verifies that the original source of the review is Google. I continue to have a pleasant relationship with these guys. Despite having to return the product they were great with me and helped me out.Posted onTrustindex verifies that the original source of the review is Google. Great company with top tier products and excellent customer service!Posted onTrustindex verifies that the original source of the review is Google. Great site and great products ❤️Posted onTrustindex verifies that the original source of the review is Google. Passionate entrepreneur bringing innovation to paramotoringVerified by TrustindexTrustindex verified badge is the Universal Symbol of Trust. Only the greatest companies can get the verified badge who has a review score above 4.5, based on customer reviews over the past 12 months. Read more

Quick-Release Prop Hubs

Quick-Release Prop Hub (2025)

This is our universal Quick-Release model designed for most pilots. There is good reason this is the most popular Quick-Release in the world. It has a bullet-proof safety record with zero failures since 2022 and it is sold and trusted by dealers all over the world (including E-Prop). It supports most 2 and 3 blade propellers.

The Quickie Prop Hub (2025)

The Quickie is our low-profile Quick-Release designed to fit into the tightest of spaces for transport. It’s designed for pilots who travel and need to break down their machine often. It fits into paramotor travel cases, shipping boxes and won’t damage your car seats. This hub only supports 2 blade E-Prop, Helix and Vittorazi propellers.

Which one is right for me?

Ergo Throttle

Our throttles are loved by many pilots because they are simple, light but most importantly extremely comfortable. They stay firmly planted in the palm of your hand, exactly where you put it because of our innovative ergonomic grip. It comes with a simple to use and intuitive cruise control and many color options. Try one and you will never look back!

Our products are engineered using modern design tools

Let’s face it. Most paramotors today are still designed for convenience and cheap manufacturing using old-school methods without testing. Many use inadequately sized fasteners, metal-on-metal moving connections, and generally incorrectly applied engineering principles. Few manufacturers perform structural testing on their paramotors, let alone applying structural design from the beginning.

Let’s face it. Most paramotors today are still designed for convenience and cheap manufacturing using old-school methods without testing. Many use inadequately sized fasteners, metal-on-metal moving connections, and generally incorrectly applied engineering principles. Few manufacturers perform structural testing on their paramotors, let alone applying structural design from the beginning.

We believe this is unacceptable.

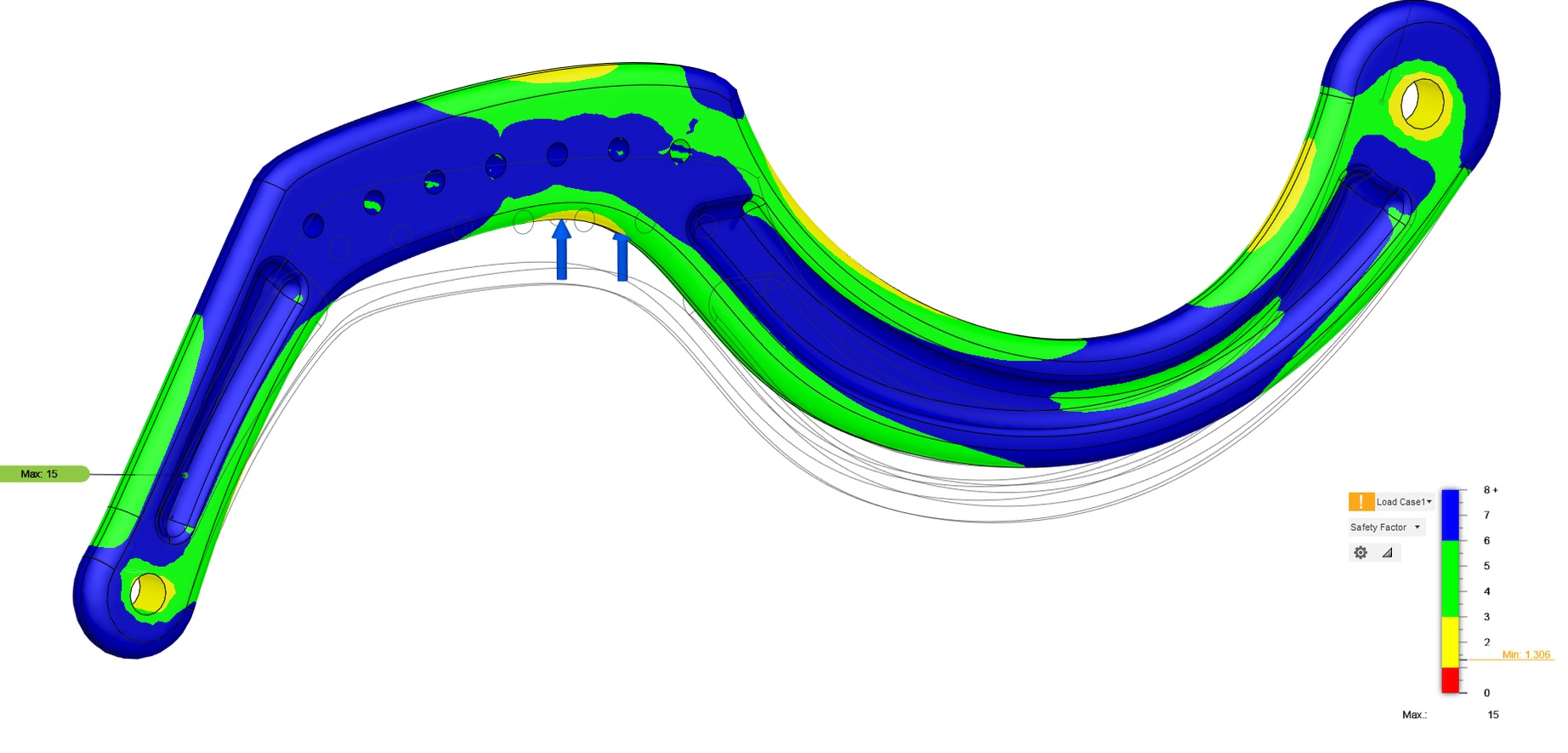

We designed the Iris Infinity using modern engineering tools and technologies. Structural components go through dozens of hours of simulations and refinement. We verify the design with real-world break testing and extensive in-flight testing. Rather than building something and seeing if it breaks in the field (especially by a customer), we set a standard and strive to achieve it.

For example, we designed our aluminum swing arms with a target breaking strength of 1600 lbs on the plate alone. With a few refinements, we overshot the engineered target to over 1900 lbs with riser offset blocks that add twisting forces. Even after the metal deformed permanently by twisting, the swing arm safely holds a load of over 1300 lbs without a notable hang angle change. This number is higher than many other swing arms on the market, even after the swing arm has failed.

Look, it’s simple

We use bushings on all moving connections

Our fasteners are adequately sized (oversized in critical positions)

Our riser offset blocks keep the carbiners nice and tidy and they are always exactly where they need to be and they don’t bang on the swing arms

Our net is strong, has full coverage and can be tensioned tightly

We use different materials based on the best material choice for a given application

We use different design/manufacturing methods based on the best choice for a given application

Our frames are modular and virtually all parts are simple and quick to replace

We use redundant safety straps

Our frame has several forms of torque compensation to fly straight under power

We have a back plate to protect your back from hitting the engine if you crash (even though it adds weight)

We care about how easy it is for you to get in and out of your seat

We want you to feel like our machine lets you connect to the wing and do exactly what you tell it instead of being a reluctant pet

We design, build and test everything in-house in the USA